Probiotic Technology

Probiotics are live microorganisms which, when administered in adequate amount, confer a health benefit on the host. While the traditional meaning of the word “probiotic” is applied to human and animal digestive microorganisms, SCD Probiotics is on the cutting edge of developing technology to apply the concept of “probiotics” to other fields including: commercial cleaning, waste management, home and garden, human health, livestock production, agriculture and other fields.

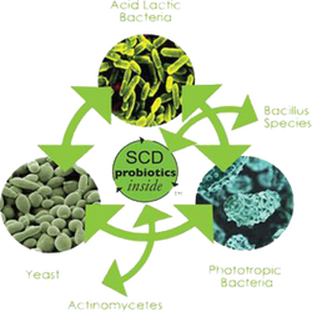

Based on a technology platform developed in Japan over thirty years ago, SCD Probiotics research and development team has spent the last ten years refining the process, using a selected number of microbial strains in consortia (co-growth environment) to produce a variety of proprietary, probiotic products. These microbial strains include lactic acid bacteria (found in yogurt and cheese), yeast (found in bread and beer) and phototrophic bacteria (found in plants).

The SCD Probiotics consortium are ecosystems consisting of balanced populations of different probiotic strains trained to live together via growth selection, which in turn translates into balanced metabolic changes of a given environment. The microbes using SCD Probiotics Technology support each other in their host environment. These cultures synergistically work to inhibit the growth of pathogenic (harmful) bacteria through competitive exclusion. In addition, the cultures contain metabolites produced by the consortia of beneficial microbes. The metabolites help neutralize toxic substances which in turn contribute to health benefits.

SCD Probiotics technology offers several distinct advantages over competitive offerings. Many of our products are listed by the Organic Materials Review Institute (OMRI) for use in certified organic production. The SCD Probiotics consortia better replicates how microorganisms exist in nature, making products more resilient than those based on pure-culture processes. SCD Probiotics products have a longer shelf life, and their ability to maintain efficacy in a wider temperature range provides competitive advantages in market development, distribution and logistics.

Probiotics are live microorganisms which, when administered in adequate amount, confer a health benefit on the host. While the traditional meaning of the word “probiotic” is applied to human and animal digestive microorganisms, SCD Probiotics is on the cutting edge of developing technology to apply the concept of “probiotics” to other fields including: commercial cleaning, waste management, home and garden, human health, livestock production, agriculture and other fields.

Based on a technology platform developed in Japan over thirty years ago, SCD Probiotics research and development team has spent the last ten years refining the process, using a selected number of microbial strains in consortia (co-growth environment) to produce a variety of proprietary, probiotic products. These microbial strains include lactic acid bacteria (found in yogurt and cheese), yeast (found in bread and beer) and phototrophic bacteria (found in plants).

The SCD Probiotics consortium are ecosystems consisting of balanced populations of different probiotic strains trained to live together via growth selection, which in turn translates into balanced metabolic changes of a given environment. The microbes using SCD Probiotics Technology support each other in their host environment. These cultures synergistically work to inhibit the growth of pathogenic (harmful) bacteria through competitive exclusion. In addition, the cultures contain metabolites produced by the consortia of beneficial microbes. The metabolites help neutralize toxic substances which in turn contribute to health benefits.

SCD Probiotics technology offers several distinct advantages over competitive offerings. Many of our products are listed by the Organic Materials Review Institute (OMRI) for use in certified organic production. The SCD Probiotics consortia better replicates how microorganisms exist in nature, making products more resilient than those based on pure-culture processes. SCD Probiotics products have a longer shelf life, and their ability to maintain efficacy in a wider temperature range provides competitive advantages in market development, distribution and logistics.

Probiotics in Cleaning

|

Biological Cleaning

Biological cleaning utilises nature's natural processes in cleaning, odor control and waste elimination without the use of potentially hazardous chemicals. Probiotics recycle waste into simple and essential substances like water and carbon dioxide. Why probiotic cleaners?

How does probiotics clean?

Our consortia microbes attack grease and grime while producing other beneficial enzymes which detoxifies and deodorises dirty surfaces. Our products generally work in 6 steps:

|

It's a Numbers Game.

On any surface, the more beneficial microorganism present, the cleaner and healthier the surface is. Outnumbering unknown and potentially disease-causing bacteria with our probiotic bacteria can lower chances of disease outbreaks. How is Probiotic Cleaners different from Enzyme Cleaners?

Enzyme-based cleaners only break down organic matter into smaller units and displaces them. They don't eliminate dirt completely. Also since enzymes are passive, they need environmental triggers to be activated properly. Biofilms

Biofilms are structured communities of bacterial or fungal cells enclosed in a self-produced polymeric matrix that adheres to both inert and living surfaces. Biofilms provide a protective shield for bacteria and fungi which allows them to thrive and resist damage from many extreme environmental conditions. Did you know that even the most toxic of all chemicals (e.g. bleach, ammonia, etc...) are not able to penetrate and eliminate biofilms? Only the power of probiotics can! Disinfectants vs Biofilms

The following video clip is a computer model time-lapse simulation of a developing biofilm made by the Montana State University, The Center for Biofilm Engineering. At the 100-hour time point, the biofilm is placed in continuous contact with a disinfectant for 15 hours. This was more than enough time for a disinfectant to kill any bacterial life. As the animation continues,'persister cells' (low metabolic rate cells protected deep within the biofilm) are seen to have a profound influence promoting the survival of the biofilm. This film demonstates the remarkable resistance of microbial biofilms to disinfectants and other chemical agents, including most antibiotics. |

|

Conclusion: Disinfectants applied on a surface do kill 99.9% of bacteria, but only for a short period of time. Pathogenic bacteria living in resilient biofilms are still very much capable of creating unhealthy surfaces.

|